Hello Riv,

Here are the spec sheets, including dimensions for our smallest solid core CT, and smallest split core CT:

BCT-013-200:

http://documents.ekmmetering.com/EKM-BC ... -sheet.pdf

SCT-013-200:

http://documents.ekmmetering.com/EKM-SC ... -sheet.pdf

most common power feed are used 208v/30amp, 2 hot (L-L) and 1 ground wires. Usually each rack has 2 separate feeds, so I am ending up with 4 hot wires and will end up installing 2 meters per rack.

- Should I still connect ground wire to meter neutral pin in this case?

No I would not substitute the ground wire for the Neutral. If you really only have 2 hot wires I would consider this a 208 volt 2 wire system, and so therefore you will only need 1 CT per install. This would be similar to a European system, you would use an Omnimeter and wire it like this:

http://www.ekmmetering.com/information/ ... ml#answer5

Are you sure this is not a 120/208 system? In this case you would have a neutral available.

You say you have 2 separate feeds, you can either meter these separately or combine them (as long as you keep the hot wires that are on the same phase running through the same CT)

In case multiple racks, example 3 racks - we will end up with 6 feeds or 12 hot wires (120v L-N or 208v L-L). Can I connect only 4 meters in this case and will they measure right values per amp, kW and kWh readings?

From this it looks like you do have a neutral (so depending on the number of hots you have, you will need 2 or 3 CTs per meter). You can get away with using as few as 1 meter to measure this, or if you want to measure the racks or servers separately you can use more meters. This is because you can measure the parallel feeds. Let me know which you would like to do.

Hint: You can tell if two wires are on the same phase by using a volt meter. If you test the wires and they are on the same phase there will be no voltage between them. If the wires on on different phases or one is a hot and one is a neutral, you will have voltage (120, 208, 240 volts, etc)

How is really bad to extend CT wire size? I need to get from 6' to something like 10'-15', but I am planing to use thicker wire, for example 18AWG. I am planning to shorter original wires from CT to a couple of inches, solder 18AWG wire instead.

I would not extend the CT wires if I could help it.

If however you absolutely need to extend the CT wires, I would recommend that you pay close attention to the connections. I would solder the wire ends together and then use heat shrink tubing to seal the joint. We have found that we lose about 1% accuracy when we extended the CT wires by 50 feet. Using larger wire will not help with the accuracy loss.

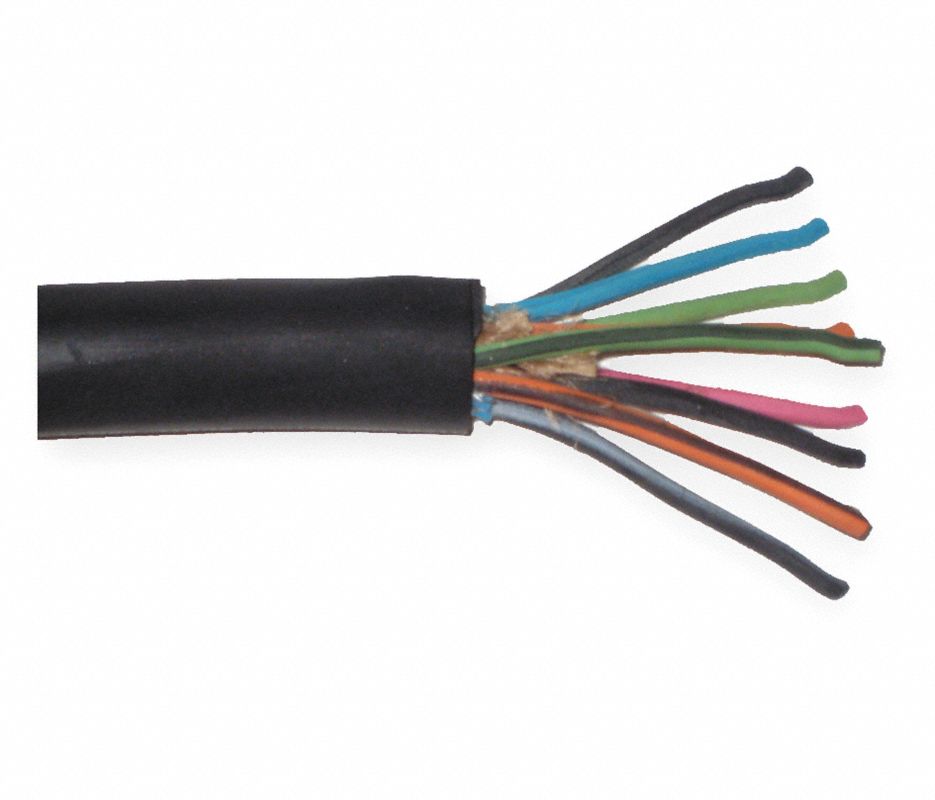

- Original CT wires are twisted. Will it give any bad impact if new extended wires will be just straight, combined into single outer jacket with other CTs and voltage wires together? Something like Carol Super 18 AWG 6-7-10 Conductor SOOW cable.

No I do not believe the CT wires have to be twisted to remain accurate. Only the RS485 data wire needs to be twisted. The twisting of the wire keeps the RS485 signal clear.